Pallställ & ställage

Ställage signerat BLS

Hur ser ditt lager ut? Det spelar egentligen ingen roll. BLS pallställage skräddarsys för att effektivisera ditt flöde. På ritbordet växer ditt pallställ fram måttsatt helt efter dina förutsättningar. Palldimensioner, typ av gods, belastning, truckgångar, golvyta och takhöjd sätter ramarna för projektet.

BLS är experter på pallställ

Visa oss din lageryta och vi skapar ett pallställ som skräddarsys efter ditt behov. Svårare än så är det inte egentligen. Genom samtal om vilken typ av pall du vill förvara och hur förutsättningarna ser ut, så skapar vi ett pallställage som hjälper dig att bli mer effektiv och konkurrenskraftig. De skickliga medarbetarna i vår småländska fabrik har byggt optimerade pallställslösningar för fryslager, smalgångs- och bredgångslager, kranlager och mobila pallställssystem för att nämna några.

Addera tillbehör för säker och smart pallförvaring

Ska du lagra stort eller smått, lätt eller tungt, frysta produkter eller rullande varor? Inga problem. Vi har tillbehör till det mesta! Exempel på tillbehör är utdragsenheter, nätplan, balkplan, avdelare, halvpallsinlägg och mycket mer. Besök BLS webshop för att se alla tillbehör.

BLS mobila system

Vill du maximera lagerytan är ett mobilt pallställssystem kanske precis vad du söker. Med mobila pallställ kan du utnyttja upp till 90 % mer av lagringsytan. Detta är möjligt genom att antalet truckgångar minimeras och golvytan därför kan användas i det närmaste fullt ut. Mobila system är ett utmärkt alternativ för exempelvis däcklager, arkivhyllor samt kyl- och fryslager.

Säkra upp pallstället

Rasskydd och påkörningsskydd är viktiga tillbehör som dessutom är krav enligt arbetsmiljöverkets föreskrifter när personal jobbar i direkt anslutning till pallställaget.

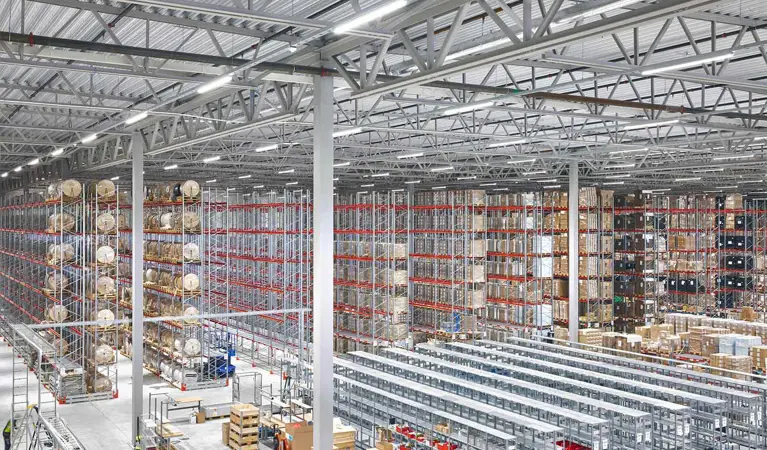

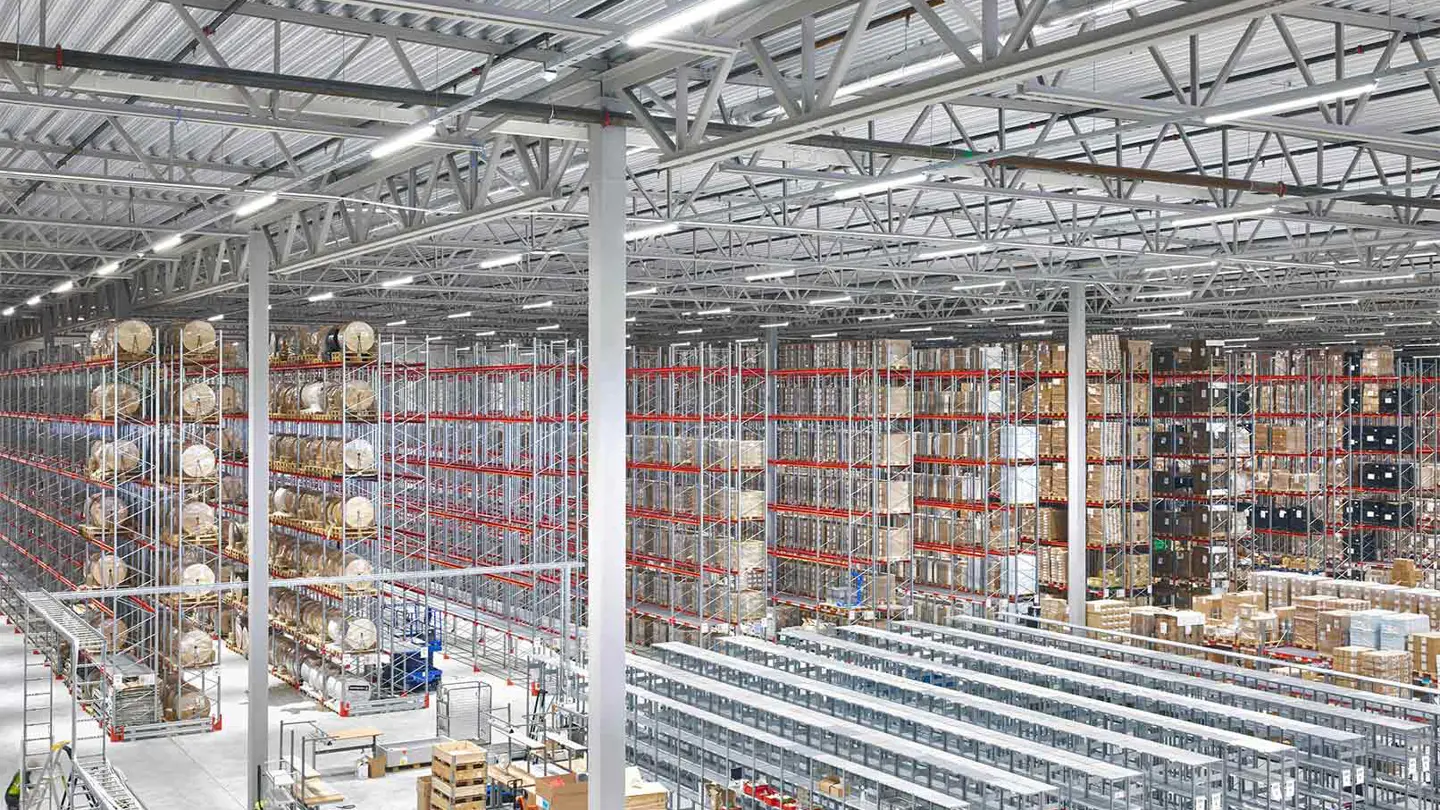

Case | PostNord TPL, Stigamo

Här finns lagerkapacitet på över 40 000 pallar

PostNord är Nordens ledande paket- och logistikleverantör. Vi fick förtroendet att skapa en skräddarsydd lösning till den 45 000 kvadratmeter stora lagerytan. Pallställ signerade BLS synkades med en autostore lösning för att skapa ett optimalt godsflöde.

Serviceavtal inkl besiktning

Vill du vara säker på att BLS-ställaget levererar på bästa och säkraste sätt efter att garantin löpt ut? Då kan du teckna serviceavtal! Med serviceavtalet förlängs garantin 1 år i taget. Besiktning och underhåll av ställagen ingår i avtalet. Skulle något behöva justeras får du veta det genom medföljande åtgärdsplan. När vi har utfört eventuella åtgärder kan du luta dig tillbaka med vetskapen om att ställaget fortsätter att hålla samma höga säkerhetsnivå ytterligare ett år.

Lär dig mer om BLS serviceavtal

BLS | Made in Småland

Vi är sprungna ur vild natur som präglas av myrmark, skogar och sjöar. Alldeles utanför fabriken ligger Store Mosse nationalpark – Sveriges största högmosseområde söder om Lappland. Här, i småländska Kulltorp hittar du vår fabrik. BLS består av ett team skickliga medarbetare som tillverkar hållbara lagerlösningar. Just här föds stommen till ditt framtida, skräddarsydda lager.

Läs mer om BLSÄr du nyfiken på hur vi kan hjälpa dig?

Har du frågor och funderingar eller vill du kanske bara säga hej? Vad det än må vara lovar vi att göra vårt bästa för att hjälpa dig. Fyll i formuläret med dina uppgifter, så hör vi av oss inom kort.

Vanliga frågor om pallställ & ställage

Vilka skydd behöver jag utrusta mitt pallställ med?

I de flesta fall behöver du utrusta ditt pallställ med någon form av skydd. Detta är dock olika beroende på vilket typ och utformning ditt lager har. Vill du veta mer? Kontakta oss då gärna så berättar vi mer för dig. Du kan även läsa mer om vilka lagar och regler som gäller för ditt pallställ på vår sida om besiktning.

Vilka tillbehör finns till att utrusta pallstället med?

Vi erbjuder ett brett utbud av tillbehör till ditt pallställ. Om du vill kan du spana in en stor del av vårt sortiment på vår webbshop klicka här för att komma dit. Saknar du något eller vill du veta mer? Kontakta oss då gärna så hjälper vi dig att anpassa ditt pallställ till de produkter du tänker förvara i stället.

När måste jag ha påkörningsskydd på mitt pallställ?

Enligt arbetsmiljölagen ska det finnas påkörningsskydd där det finns risk att köra på ställaget. Detta innebär att påkörningsskydd ska finnas där det förekommer mekaniska in-och utlastning med truck eller annan liknande utrustning. Det behöver alltså inte finnas vid exempelvis manuellt handlastande av material i ställaget.

Måste jag besiktiga mitt pallställ?

All lagerinredning ska årligen besiktigas. Läsa mer och boka din besiktning här.

Vad är viktigt att tänka på vid köp av pallställ?

Det är viktigt att tänka på vad som ska förvaras i ditt pallställ och hur tungt godset är. Pallställ är väldigt flexibla, det finns många tillbehör som gör att de kan anpassa efter lagringsbehovet. Pallställets gavlar och balkar klarar dock bara upp till en viss belastning beroende på vilken maxlast du väljer att köpa. Det gör att det kan vara bra att fundera ut innan hur tungt du kommer behöva lasta ditt pallställ.

Är det okej att byta ut påkörda komponenter i mitt pallställ?

Ja, skadade komponenter är okej att byta ut. Skadade bärande delar ska bytas ut omedelbart eftersom det utgör en säkerhetsrisk. De delar på pallstället som inte är skadat behöver inte bytas ut.

Hur höga pallar får plats i pallstället?

Eftersom du enkelt kan justera balkarna i höjdled kan du själv bestämma vilken höjd det ska vara mellan de bärande nivåerna. Detta gör att det inte är höjden på pallarna som lär vara ett problem utan maxlasten i pallstället och att höjden på gavlarna är tillräckligt höga.